Angeles City Cabinetmaker Building European Style Kitchen Cabinets, Office Cabinets, and CR vanities

U.S. Style Cabinet Company was formed after the owners Flordeliza Selumin and Jannyn Selomin had managed another cabinet manufacturing shop out at Clark Freeport Zone for CSMFG, Inc. There they produced cabinets and components for four years in export grade quality for a U.S. based company.

The two sisters then organized a new shop with the blessing and assistance of their former employer to service the local market by producing export quality grade kitchen and CR cabinets. The locally available choice for kitchen cabinets is limited to a few local cabinetmakers that are lacking in experience and vision and of course imported Chinese cabinetry which does little to support the local economy. Indeed these imported cabinets send much needed foreign currency out of the Philippines and exposes the customers and their family to substandard Chinese quality and lord knows what chemicals in their particle board and paint.

So the local market in Pampanga needs a quality cabinet shop that brings in new ideas and better quality construction processes. The local shops use antiquated methods, cutting parts by hand when a proper machine is needed for accuracy. Their finishing is done without a proper spray booth, with cabinets being sprayed improperly, leading to poor interior finish and substandard exterior finish thickness. Flor and Jannyn are bringing a much better quality cabinet to the market.

Call us at Globe Cell Phone number 0 916 741 4266

Here is a video of the showroom sample set pictured above. Just click on the blue link. The set above costs, unfinished cabinets, 39,999 Pesos, paint finish add 8,000 Pesos, countertop and sink add 25,000 Pesos, installation 5.000 Pesos, knobs and pulls 2,000 Pesos. Total price completely painted and installed 79,999 Pesos. The installation isn’t difficult, if you have a way to haul the cabinets you can install the cabinets yourself.

We are just now building the showroom samples and the showroom itself so pardon our progress when you visit the showroom. The picture above is the first showroom set, sized to fit the Xevera Mabalacat condos. There is a space for a 30″ stove or the opening can be sized for any width of cook stove or range. You could put a blind corner cabinet in that corner, this set just has an empty space behind it to keep the price down as low as possible. A dishwasher could be placed where the cabinet to the left of the stove opening is. If an exhaust hood is wanted the upper cabinet can be made shorter to provide extra room.

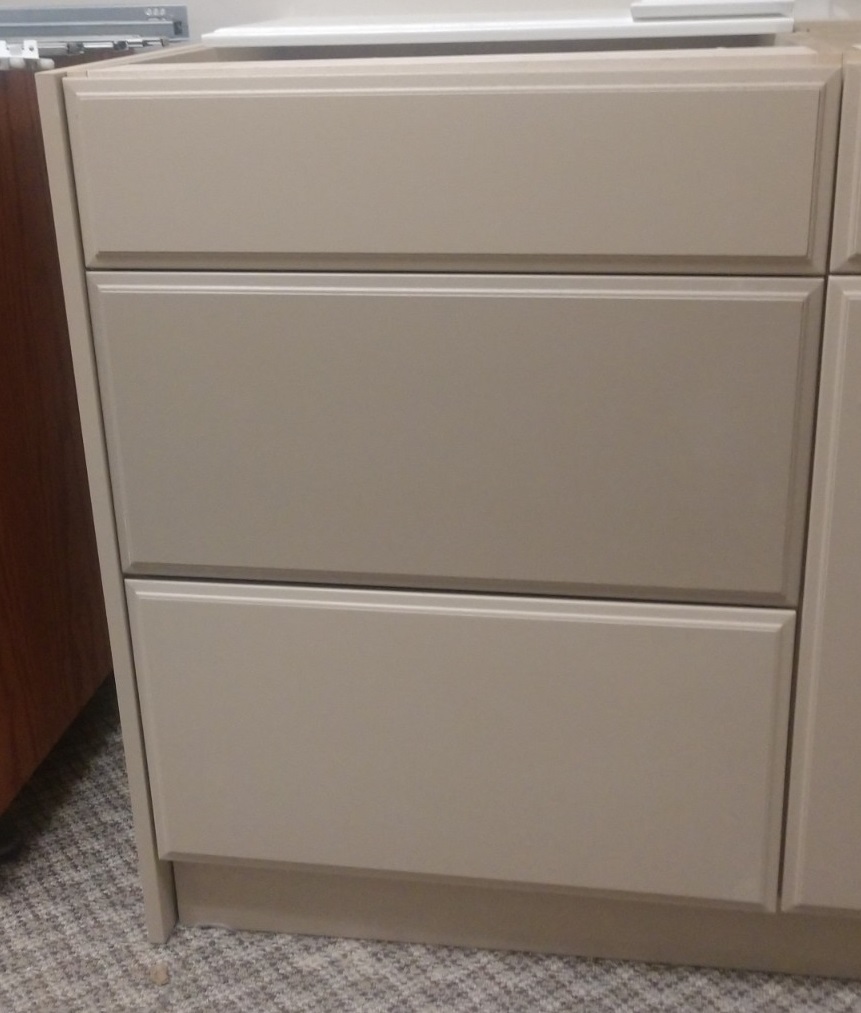

That set has five part doors and five part drawer fronts, plain end panels, and is made of 3/4″ thick marine plywood for the carcass and MDF for the exterior parts for smoothness.

Our Cabinets

We build MDF and Marine Plywood cabinets with little natural wood to help minimize termite damage. Termites don’t like the glue in the engineered products. However, if you are going to invest in quality woodwork in your home you should treat for termites and have the home in good condition and keep the home dry inside.

Do you want to see some of our work? Just click on the blue text below to learn more

Countertop info, click on this link please

U.S. style modular kitchen cabinets Click on this blue link

Showroom Pictures, Click on this blue link

Walk in Closets click on this blue link

We can build very complex and expensive trophy kitchens or we can make a basic set of cabinets that enhances the value of the home and makes the home a joy to live in.

U.S. style vanity cabinets for the CR

If you are going to consider putting wood cabinets in a CR it can be done only if you first make sure the CR stays dry! That means separating the shower area from the vanity that holds the sink.

U.S. style office and library cabinets click on this link

We can build office cabinets for both home offices and commercial offices as well as library cabinets for storing books or binders, either in high style or as a basic commercial style. Click on the blue heading above, it is a link to our Office cabinet information page.

The available kitchen cabinets in the Pampanga area are not suitable for export and frankly quite expensive for the level of quality. The average Pampangan has the choice of expensive but poor quality imported Chinese cabinets assembled and modified by a local re seller or locally produced cabinets made with hand held circular saws by hardworking and enthusiastic workers without proper equipment or supervision.

A job starts off with carefully measuring the walls in the room the cabinets are to be installed in. The details are entered into a powerful kitchen cabinet software package that generates a scale drawing of the room and the cabinets are drawn and the drawings are shown to the customer to ensure all the details are exactly as the customer requires. Then the same software generates detailed cut lists and a bill of materials. The job then goes onto the shop floor for production.

Proper equipment allows the quality to be built into the cabinets with each step. This starts with panel saws capable of cutting straight and square parts in accurate sizes. Using a straight edge and a hand held circular is difficult even with a skilled worker, the cuts will not be square, the parts produced will be of varying width, even the squareness of the edge will suffer. A proper panel saw has a five horsepower motor rigidly held in place in a frame running on precision ground linear shafts with linear bearings. The motor is powerful enough that it spins at full speed which keeps the blade straight and square while a powerful dust collector pulls the sawdust out of the way.

Next the panels have the finished edges edgebanded and the system holes are drilled into the end panels. System holes provide locating holes for all the hardware, hinges, drawer slides, and shelf pins. These holes are crucial for the European system of cabinet making so the holes are drilled using precision drilling fixtures containing hardened steel drill bushings.

The pictures to the left are some of the thousands of cabinets and cabinet components that Flor and Jannyn produced and exported while working for the U.S. based cabinet company called CSMFG, Inc. The tan colored cabinets are slab door, slab drawer front style cabinets. The white set is the five part door style with slab drawer fronts.

Nearly all of the shelves are adjustable, the drawers boxes have metal sides for durability, with 3/4″ thick painted MDF drawer bottoms and adjustable drawer fronts. The hinges are all concealed European style hinges with adjustment screws to move the doors up, down, in and out, and side to side. Drawer fronts can be adjusted a small amount up and down and side to side. These drawers are strong and very durable. Far stronger than a wooden drawer that will warp or get eaten up by termites.

A corner cabinet measures about 31″ x 36″ x 36″ so be sure you have a large enough front door to get the cabinet through. A 36″ wide front door is needed, the cabinet can be turned on its side to get the 31″ side through the front door. You can add lazy susan turntables, usually two shelves, the one in the picture only has one shelf. The upper cabinets are hung on steel rails or brackets that attach to the wall and there are suspension brackets inside the upper cabinet to adjust the height and level of the cabinets.

The toe kicks at the bottom of the cabinet can be removed in most cases for running wires, water lines, or just spraying for bugs. The stove ends are left uncovered to provide some ventilation to help prevent mold build up. You do need a dry location to install good cabinets and the sink drain needs to be working properly. It is a good idea to fix any leaks in the drains or roof prior to installing expensive cabinets. The engineered marine plywood and MDF will handle normal humidity just fine.

With the parts cut to size, edgebanded, and drilled, the cabinets carcasses or boxes are assembled. At that point the doors and drawer fronts are laid in place on the cabinet boxes which are laid on their back to ensure a good fit on the exterior parts. Then the drawer fronts, doors, end panels, fillers, and trim are carefully sanded and sent into the finishing department.

Finishing is done with an air assisted airless sprayer, imported from the United States. The sprayer lays down a fine coating of paint with all exterior parts being sprayed flat so that the maximum thickness coating of paint can be applied. All end panels are pre finished before installation for that very reason so the paint is nice and thick.

Once the first coat of paint is dry the painted parts are sanded by hand. The paint is a lacquer based product but the grain on the wood will raise but the paint locks the fibers in place as it dries so the sanding leaves a smooth finish. A second coat is sprayed and sanded as well to ensure there are no thin areas or sharp edges left uncovered. Then a sealer coat of clear lacquer is applied before being sanded once again before the final coat of lacquer is applied.

Next the backs are installed in the cabinets, the backs being left out to allow the spray booth to pull the overspray out and leave a smooth finish. Drawer slides and hinge base plates are installed and the drawer boxes, drawer fronts, and doors are installed. The cabinets are set up on their feet ready for an inspection from the customer. Upper cabinets are set in place on top of the bottom cabinets so the customer sees the entire set and can judge the finish quality and ensure the cabinets came out exactly as the drawings said they would.

If you are interested in an estimate for your kitchen or CR cabinets please provide some rough measurements and a few pictures of the existing cabinets or areas. Or if you find pictures on the internet of what you are looking for you can email us the pictures to see if we can match the style. We can do a rough quote with that information. If you like the price we will visit your home to verify all measurements and create a formal estimate for your consideration. It is nice to have all the appliance sizes on hand and have your paint color picked out.

At that point we create the drawings for your approval. You will have elevations, which are drawings of each wall of the set of cabinets and an overhead view of the entire set of cabinets. We might need to make paint samples for you as well. Once the drawings are approved, you sign the drawings and we use them to ensure the cabinets come out the way you wanted them to.

The next step is the deposit for building the cabinets. You put 50% of the unfinished cabinets down as a deposit. Once the cabinets are built and ready to go into the finishing room you will come by to do an inspection of the cabinets and to pay the second 50% payment. The cabinets will be laid down on their backs in order, with the upper cabinets laying above the lower cabinets so you can see exactly how it is going to look. All the doors, drawer fronts, and end panels are laid in place so you see what the set of cabinets looks like.

Once the cabinets come out of the finishing room the cabinet backs will be installed and all the doors and drawers installed. Then the cabinets will be set up in order, with the upper cabinets sitting on top the lower cabinets so you can see exactly how it is going to look. Once you approve the finished cabinets you pay the finishing charges and the cabinets are either picked up if you are going to do your own installation or we schedule a delivery and installation.

The installation will take about two to three days. If you are having us make you a solid surface countertop we will make a wooden countertop template once the cabinets are installed and it will take two to three working days to build the countertop and get it installed. You pay a deposit on the countertop, 50% of the cost, usually around the time that the cabinets go into the finishing room so we have time to get the countertop sheets delivered from Manila. The second half of the countertop is paid immediately after we install the countertop.

You can purchase your own sink or we can pick one out for you. Be sure it is a drop in sink, not an undermount as undermount sinks cost extra to install. Some sinks come with an inexpensive faucet or you can buy just the sink and purchase a quality faucet that is likely to last longer.